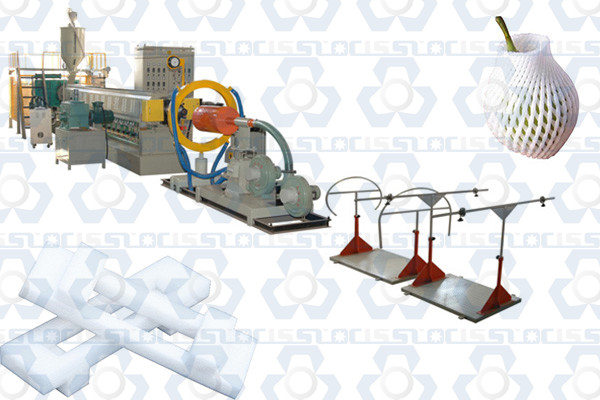

CO2 Foaming Fully Automatic XPS Foam Insulation Board Production Line

-

CO2 foaming without freon;

Full-automatic downline;

3-4 people control all the line;

Density of board: 28-40kg per cubic meter. -

1 Material data:

1.1 Polymer: Suitable PS pellets grade

1.2 Blowing agent: CO2+Alcohol+HFC (if needed, and no HFC is also ok)

1.3 Additive: Normal Granules or powder with free Flowability.2 Performance data:

2.1 Capacity: 400-1200kg/hr, depending on specific polymer grades and foam agents applied.

2.2 Thickness of board: 20-120mm.

2.3 Width of board: 600mm, 1200mm.

2.4 Max. line speed: 24m/min. -

-

Product output400-600kg/hr 700-900kg/hr 800-1200kg/hr

-

Screw diameterФ85/Ф200 Ф95/Ф250 Ф110/Ф300

-

Width of sheet600mm/1200mm

-

Thickness of sheet20-150mm

-