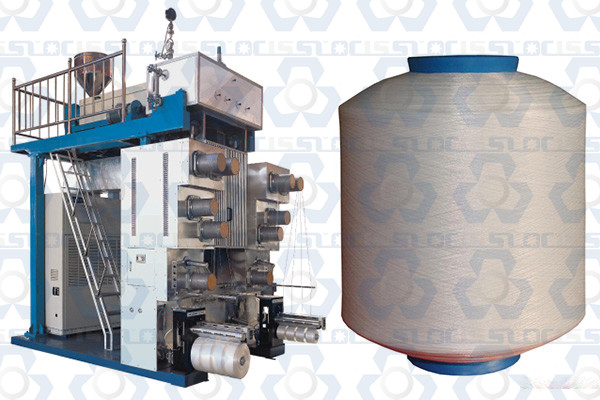

YJ-1000M DTY Machine

-

Usages: The machine will be made of polyester (POY), polypropylene and other non-twist raw silk, which can be transformed into elastic wire with medium and low elasticity. If add network part also can undertake network silk processing.

-

Feature:

- 1.The first heater (deforming heater) and the second heater (setting heater) adopt biphenyl air heating. The computer

- controls the heating and temperature control. The precision of temperature control is +10C, assure every spindle's temperature to be almost same. This is beneficial for even dying.

- 2.The machine has the features of simple structure, reliable transmission ratio, low noise level and easy technological adjustment.

- 3.The advanced designed electrical control system makes the operation simple, running reliable. Man - machine interaction can be realized by touching screen.

- 4.Two sides of this machine are relatively independent. The technology can be set separately. Different types and denier texturing yarn can be processed at the same time.

-

-

Quantity of spindles240spindles standard),264/288spindles

-

Mechanical Speed1000m/min(W2 feed roll speed)

-

TwisterType 8 disc friction unit

-

First heaterDiphenyl/2000mm

-

Second heaterDiphenyl/1460mm

-

Spindle gauge110mm

-

Cooling rail length2100mm

-

Diameter of take-upΦ100mm

-

Oil roll diameterΦ75mm

-

Feed roll diameterΦ75mm

-

Section distance1440mm

-

Denier range55-330Dtex

-

Package of take-upΦ250*250mm

-

Size: long x wide x18780*6724*4895mm

-

Installation power212.5KW

-