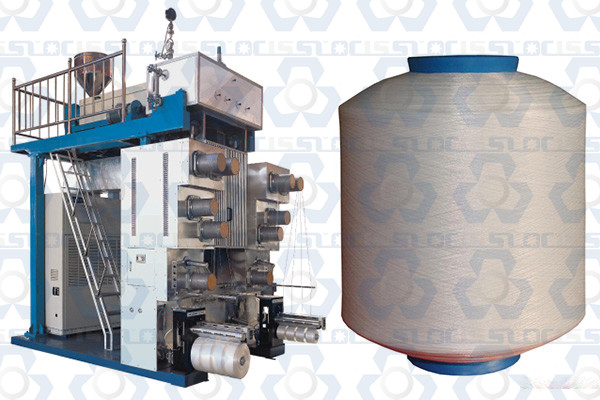

PET PP PA6 Blanket Carpet BCF Yarn Production Line, BCF Yarn Draw Off Machine, BCF HEAD

-

Used for producing PP PET PA6 BCF yarn by processing of extruding, melting, spinning and drawing, consists of spinning machine, bcf draw off machine and winder.

-

Characteristics:

-

Using the modular process and design system to be flexible;

-

Quenching with gradient design to ensure the yarn of better cooling performance;

-

Hot godet heated by high frequency multi-zone temperature control, the surface temperature uniform and energy saving;

-

Advanced texturing technology, curl is soft and smooth, uniform and high coverage;

-

The design of the large diameter of the cooling drum to make the batter finalize the bulk yarn;

-

Using the world's advanced tangle jet to ensure the link uniform solid;

-

Using JHW B600/2 and JHW B920/3 series automatic winder, high success rate for switching, tension fine-tuning precision, good figuration;

-

This equipment has running stabiligy, long life, high cost performance and other advantages.

-

-

-

ApplicationsPP, PA6, PET

-

Denier range800-3000D

-

Spinning speed1300-2600m/min

-

CrimpnessMax. 25

-

Hot-godet precision+/- 1 degree

-

Masterbatch meteringVolume/Weight

-

Tangle jetTemco/RPE

-

Monochrome2/3 ends/winder

-

Mixture3 ends/winder

-

Tube specificationφ75*φ82*290/ φ73*φ80*290

-